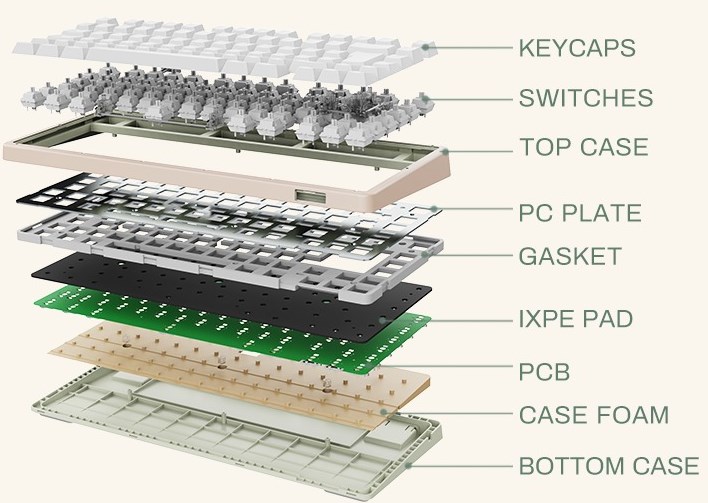

The Minilo 75 is Varmilo’s latest artistic design product, featuring the Morandi color, gasket mount, and it’s hot-swappable. Gasket mount is the significant improvement since it brings to better typing feel and sound of the keyboard. Now let’s explore what gasket mount is and its irreplaceable advantages.

What is a Mounting Style?

First of all, a keyboard’s mounting style is how to secure the plate or PCB in the keyboard housing. Since it has to secure these components within a keyboard, the community has developed several ways to do this. Some are more rigid or flexible than others, affecting the assembly method, sound, and even typing feel of the board.

There are two main categories of keyboard mount structure: Case mount and Tray mount. In terms of design, there are two types: Plate and Plateless. Case mount, as the name implies, refers to fixing the internal components (such as the mounting plate and PCB) onto the keyboard case. Tray mount, on the other hand, is like placing food on a tray, where it fixes the components onto the bottom plate of the keyboard’s chassis. A Plate design includes a mounting plate, while Plateless, also known as “no-plate,” does not have a mounting plate. In most Case mount and Tray mount keyboards, we secure the mounting plate and case together using screws.

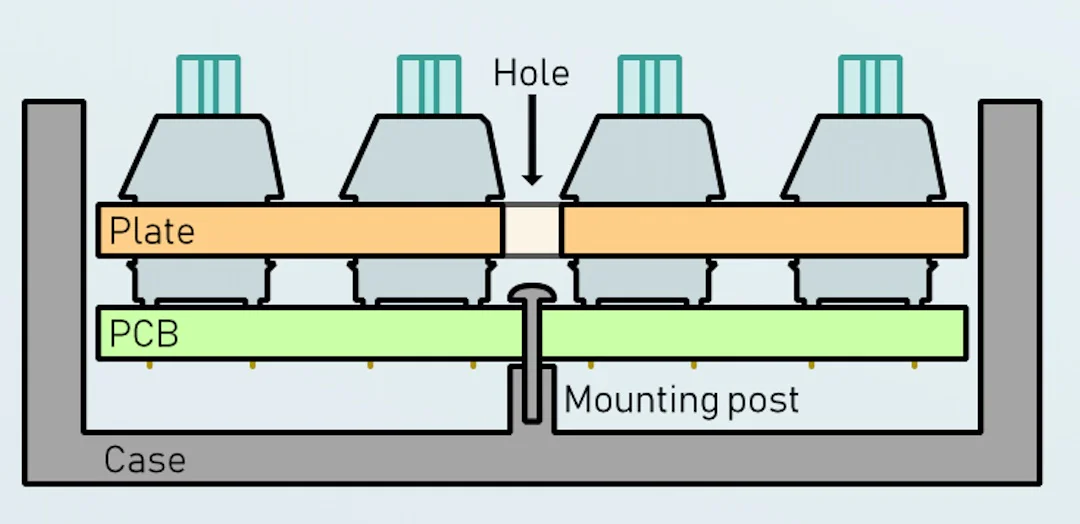

Tray Mount

Tray mount is a structure that is very simple yet widely used. The keyboard does not have an upper and lower case distinction and is generally composed of a bottom case, PCB, and mounting plate. The bottom plate of the keyboard’s chassis has screw holes, and screws pass through the mounting plate and PCB to secure the entire keyboard. In order to assemble together, the PCB, mounting plate, and case share the same screw positions. The GH60 is the most famous Tray mount specification, also known as the “Standard 60% Layout.” Any mass-produced 60% keyboard will have some level of compatibility with the screw hole positions of the GH60, sharing at least 3 screws. Examples of keyboards that utilize this installation method include Poker, Anne, and DC60. Vortex’s 60% keyboards were the first to introduce this mounting method.

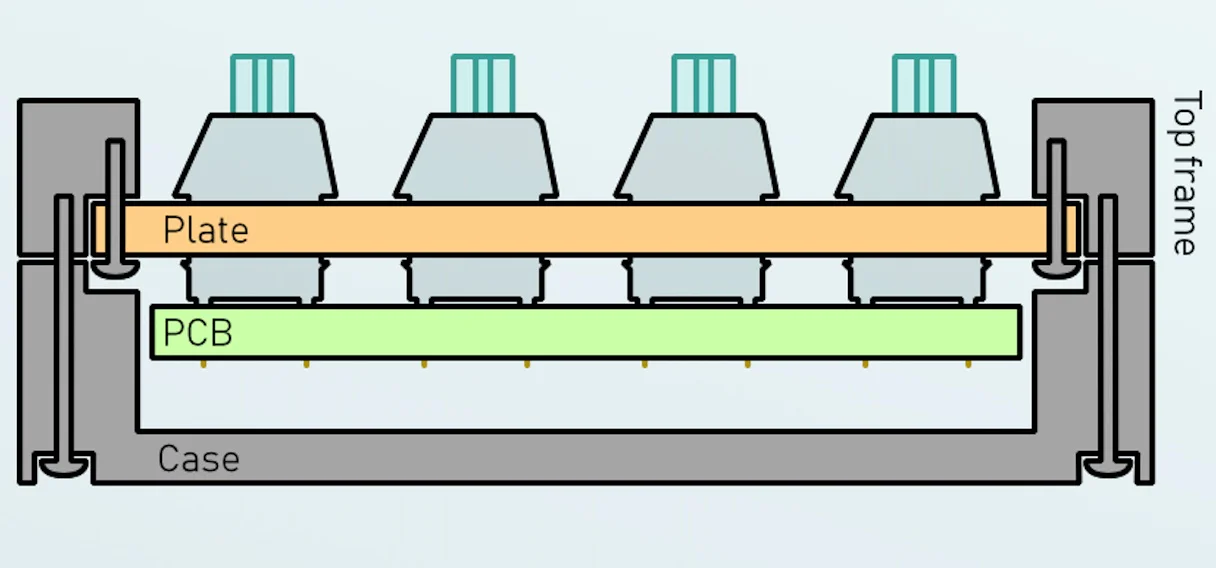

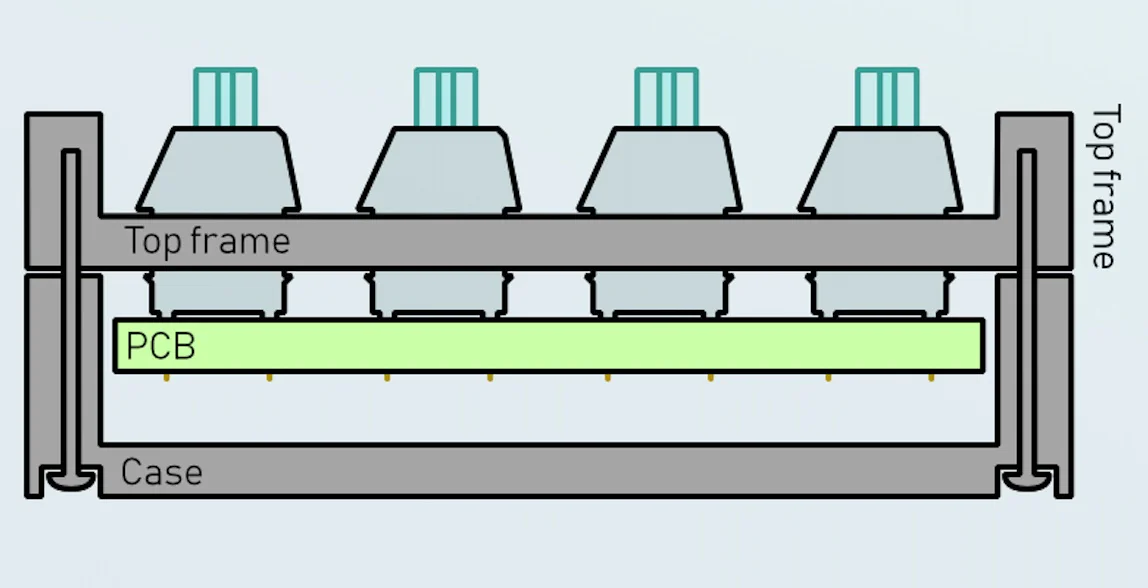

Top Mount

Fixing the mounting plate to the top cover. This type of mounting plate typically has mounting tabs with screw holes, screwed onto the top cover. It makes screws threaded through the top cover and tightened onto the bottom case to complete the keyboard assembly. This structure is widely used in the customization of high-end and mid-range keyboards due to its excellent tactile feel and relative ease of manufacturing.

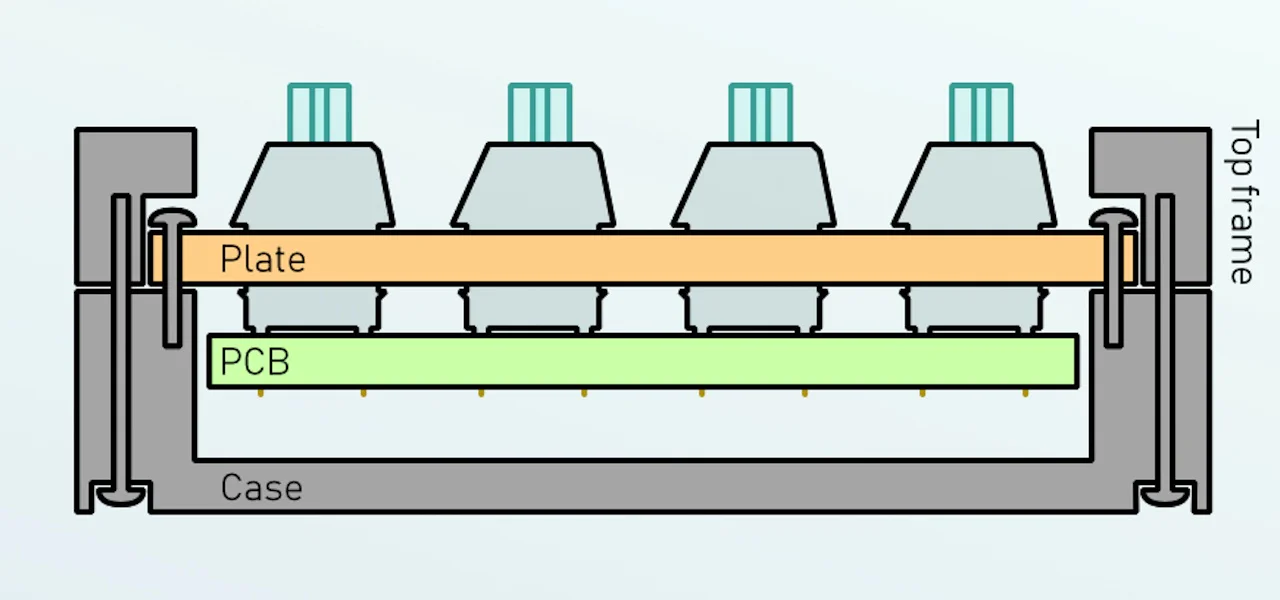

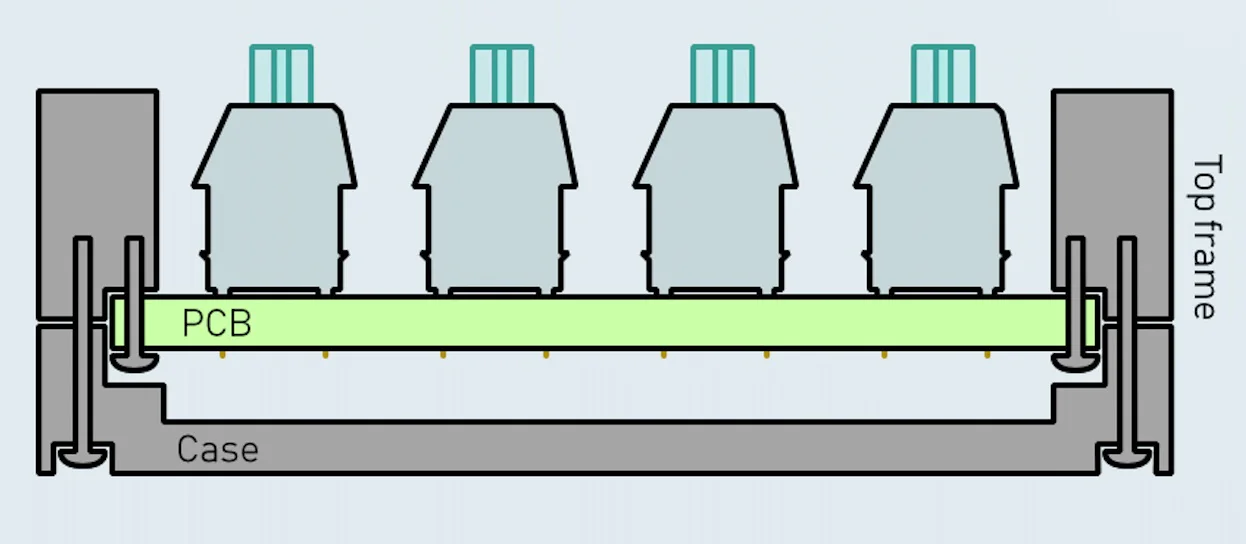

Bottom Mount

In contrast to top mount, bottom mount the fixes internal components to the edge of the keyboard bottom case. In this structure, the keyboard’s internal assembly typically has mounting holes, while corresponding screw holes are present on the bottom case. By threading the screws through the mounting holes and tightening them onto the bottom case, it securely fasten the internal components are to the bottom, completing the keyboard assembly. This structure is also widely used in high-end keyboards, providing a stable keyboard construction and excellent typing experience.

This structure is somewhat similar to Tray mount, but it is not fix to the bottom case, allowing for a greater and more uniform rigid support structure. Additionally, this structure does not require the involvement of a top cover, enabling the design of a floating-style appearance. Personally, I find it to be slightly firmer than Top mount.

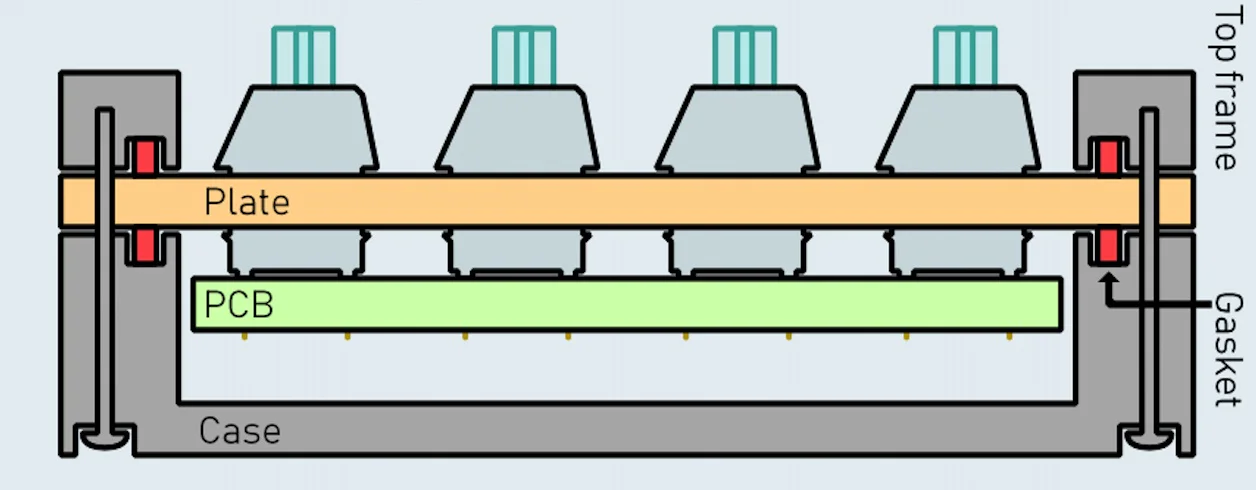

Sandwich Mount

Securely fastening the mounting plate between the top cover and bottom case.

Sandwich mount is much more complex than it sounds because the mounting plate needs to fit seamlessly along the edges of the case to ensure perfect alignment while still allowing a slight flex for cushioning. Since both the top and bottom case connect to the mounting plate, sandwich-structured keyboards can better suppress vibrations from the bottom, resulting in unique and pleasing bottom-out sounds.

Integrated Mount

Integrate Top case and plate together.

Integrated mount does not have interchangeable mounting plates for color coordination with the top cover and bottom case. This is because the mounting plate and top cover are milled from the same piece of aluminum/PC/titanium or whatever material, creating a texture similar to a sandwich structure. Since the mounting plate in Integrated mount is continuously constrained by the surrounding elements, it provides a firm bottom-out feeling similar to a sandwich structure. However, it is limited to the top being constrained rather than being constrained from all sides like a sandwich structure. Integrated mount keyboards usually have a more pronounced typing sound. The manufacturing cost is slightly higher compared to top/bottom mount due to the increased CNC machining time.

Plateless Mount

Strictly speaking, Plateless mount is a design rather than a structure. It can be Top mount, Bottom mount, Gasket mount, or even Tray mount. The only difference it has from other mounts is the absence of a mounting plate. When pressing the switches, the sensation is directly transmitted to the PCB, resulting in a unique and elastic feel. This design requires high precision in PCB cutouts and generally does not support hot-swapping. Otherwise, there is a risk of misaligned switches or pulling out the switches along with the keycaps when removing them.

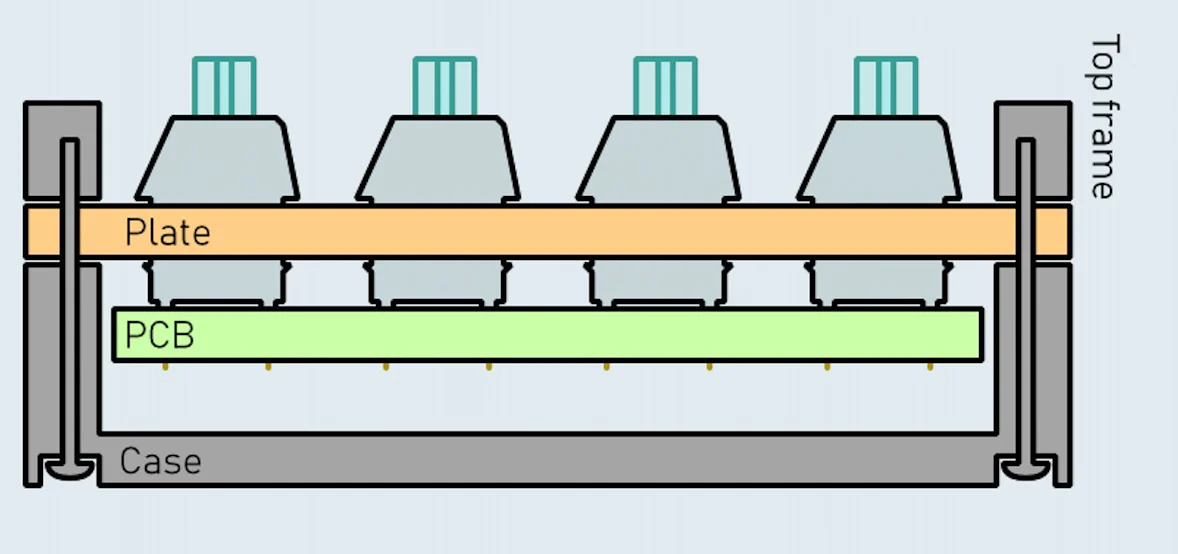

Gasket Mount

A gasket mount uses gasket material between the plate and keyboard housing on both top and bottom sides. This gives the board a slightly more cushioned feel since the plate isn’t in direct contact with the other metal components of the keyboard.

A gasket mount uses gasket material between the plate and keyboard housing on both top and bottom sides. This gives the board a slightly more cushioned feel. Since the plate isn’t in direct contact with the other metal components of the keyboard.

The screws only hold the keyboard case together, while the internal components lack a rigid structure and screw support. Instead, they rely entirely on rubber and the precise fit between the upper and lower covers to secure them within the keyboard. This results in an extremely uniform typing experience. And due to the rubber gaskets, there is cushioning in both the vertical directions, providing a smoother tactile feel.

It’s no wonder that this layout has become so popular recently. The Volcano 660, created by the TYL customization team, was one of the earliest keyboards to feature this design. However, the cost of manufacturing such keyboards is very high due to the multiple iterations of prototyping required to calculate tolerances, create molds for the rubber damping pads, and select the appropriate hardness. As a result, it requires a highly skilled and capable team.

Raindrop Sound

Another significant advantage of gasket mount is that the keyboard’s typing sound becomes reminiscent of raindrops falling or the sound of small stones colliding. This makes typing on a gasket mount keyboard a delightful experience. You can experience it through the video below. Many enthusiasts liken this keyboard sound to high-fidelity (HiFi) music and refer to such keyboards as “sound actors” or “voice actors.”

Other advantages of gasket mount:

- Increased Flexibility: The gasket layer allows for slight movement and flex within the keyboard. it provide a more forgiving typing experience that reduces fatigue during long typing sessions.

- Vibration Isolation: The gasket mount effectively isolates the PCB from the case, minimizing the transmission of vibrations and reducing unwanted resonance, resulting in a cleaner and more refined sound.

- Customizability: Gasket mount keyboards often offer customizable gaskets, allowing users to fine-tune the typing experience according to their preferences. They can experiment with different gasket materials, thicknesses, and hardness levels to achieve their desired typing feel.

Overall, gasket mount is valued for its ability to enhance the typing experience, improve sound quality, and provide a unique and enjoyable typing sensation. It has become a popular choice among keyboard enthusiasts seeking a premium and refined typing experience.

Meet The Best Gasket Keyboard – Minilo 75 Series

The Minilo 75 is Varmilo’s latest artistic design product, featuring the Morandi color, Gasket structure, and it’s hot-swappable switches.

Gasket Mount

Morandi Color

Hot-Swapable

The hot-swappable feature of the Minilo 75 allows for easy and convenient swapping of different switches without the need for soldering. This means that you can effortlessly change the switches on your keyboard to experience different typing sensations and customize it to your preferences.

Additionally, hot-swappable keyboards like the Minilo 75 offer the convenience of switch replacement. If a switch becomes faulty or if you simply want to try a different switch type, you can easily swap it out without needing any specialized equipment.

Not sure how to choose mechanical keyboard switches? Take a quick read of this article! The ultimate guide to mechanical keyboard switches for 2023 : Varmilo

Conclusion

This article explains the various mounting structures of mechanical keyboards and highlights the advantages of gasket mount. Want the best gasket mount keyboard? Why not consider purchasing the Minilo 75 series directly? Shop now!

Any chance to get some of these new Varmilo keyboards in ISO-French ? I have a VA88M Charcoal that is perfect for work, looking to get a new one for gaming ! Your switches / lubrification process is really good

You may custom one here, https://en.varmilo.com/keyboardproscenium/fastcustomization